Coating

Our Coating Services

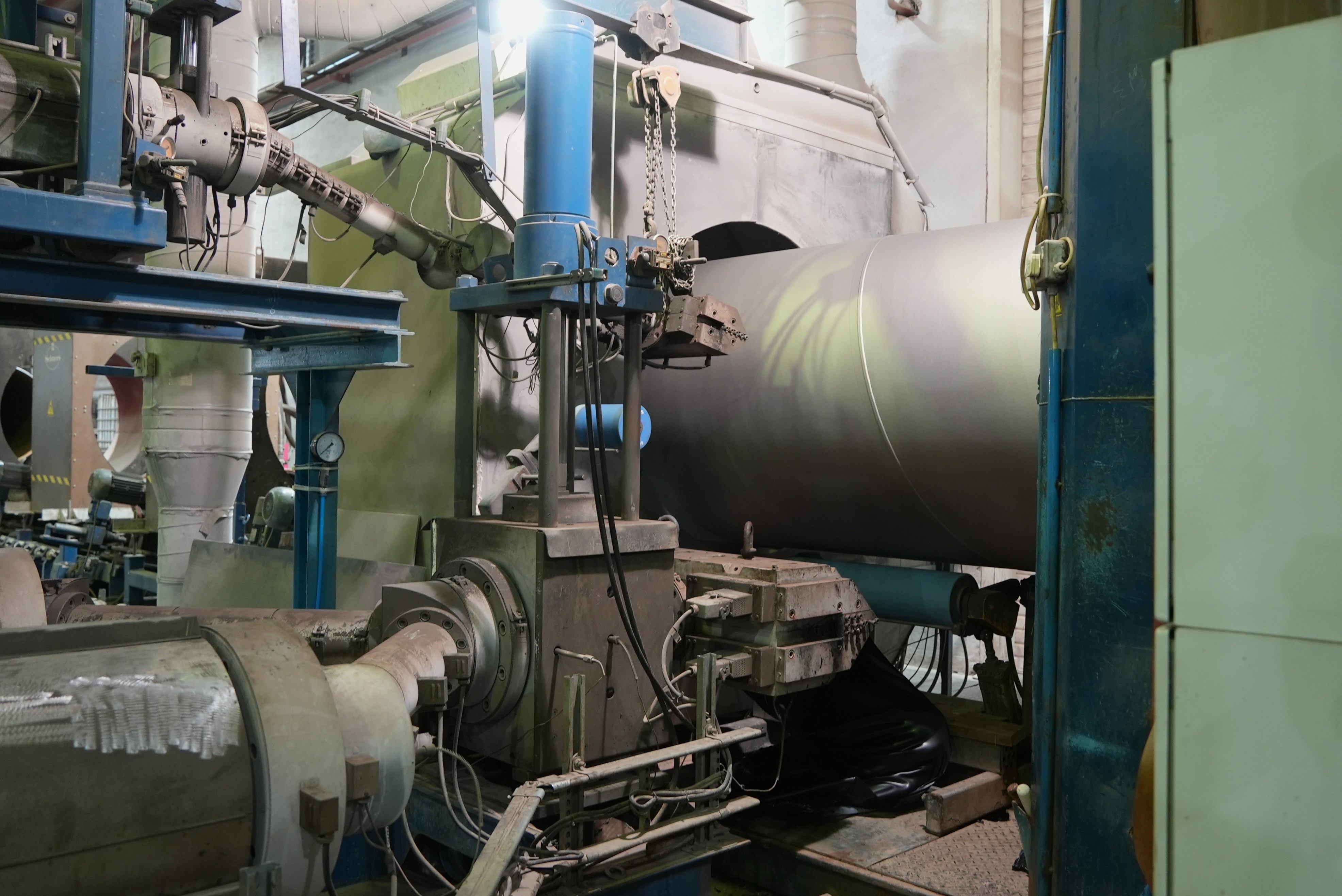

Advanced Pipe Coating Solutions

Pipe coating and lining is of fundamental importance in the protection of pipes against corrosion environments and the pipes' life length that depends directly on its coating. MPI is fully equipped to apply different types of coatings and linings in accordance with the major international standards in order to meet the requirement of its customers.

Coating Types

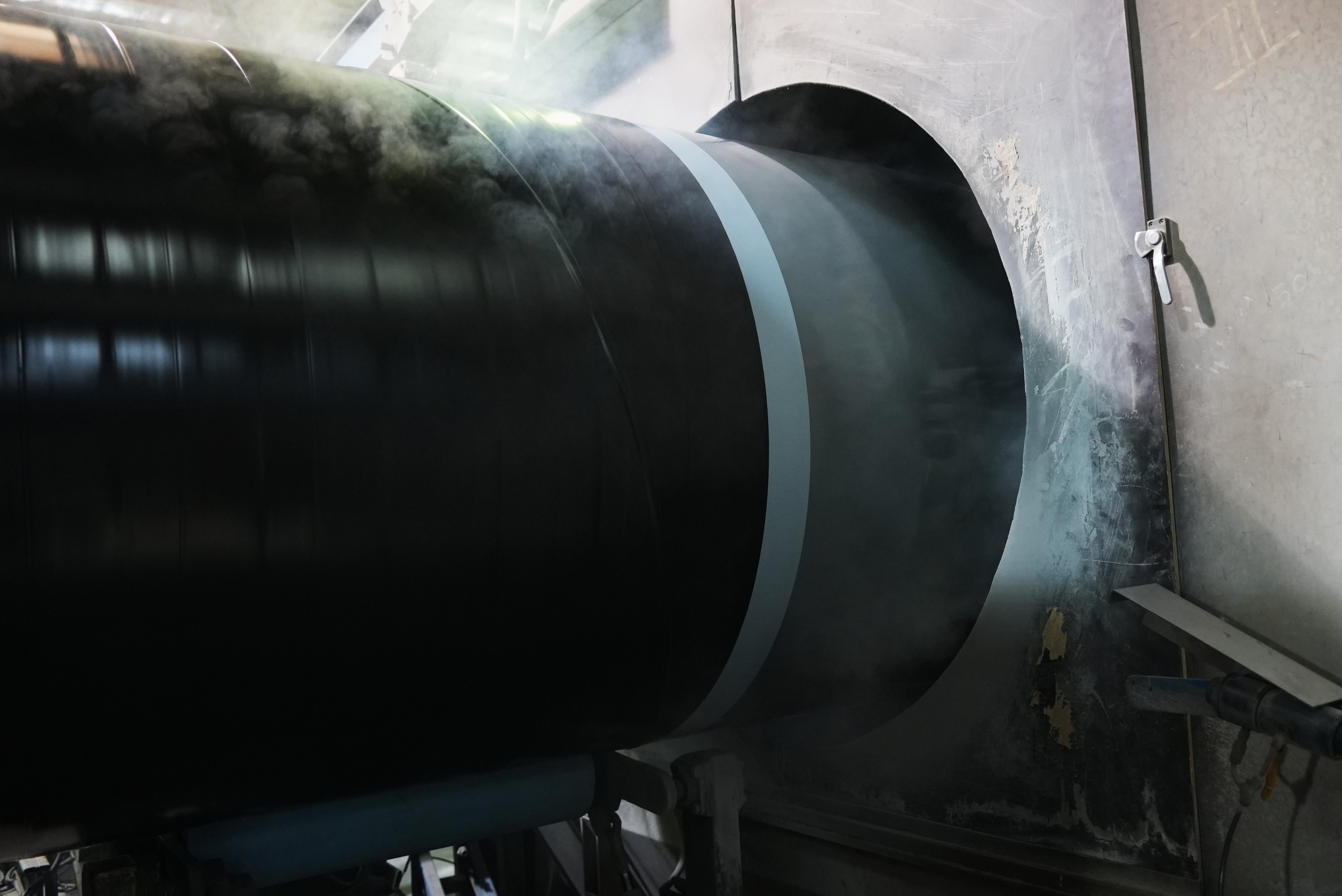

i) External Polyethylene Coating

(PE) coating is extremely efficient against corrosion and aggressive environments and chemical material. PE coating is applied in accordance with DIN 30670 and as per KOC Specification KOC-P-004 Part 6 Rev. 4 to customer requirement using three-layer polyethylene extruded coating system. The production ranges from 4 inch up to 64 inches.

ii) External Polypropylene Coating

3LPP Coating applied in accordance with DIN 30678 or KOC Specification KOC-P-004 Part 6 Rev. 4. The production ranges from 4 inch up to 64 inches.

iii) External FBE Coating

Dual Fusion Bonded Epoxy, stand-alone External Coating on steel pipes in accordance with KOC Specification KOC-P-004 Part 4. The production ranges from 4 inch up to 64 inches.

Application of Coating for Pipes:

| Specifications No. | Coating Type | By |

|---|---|---|

| KOC-P-004 Part-6 Rev. | 3LHDPE/ 3LHDPP | KOC |

| KOC-P-004 Part 4-Rev.3 | DFBE | KOC |

| SHELL DEP 31.40.30.31 | 3LHDPE/ 3LHDPP | SHELL |

| DIN 30670 | 3LHDPE | DIN |

| DIN 30678 | 3LHDPP | DIN |